Details

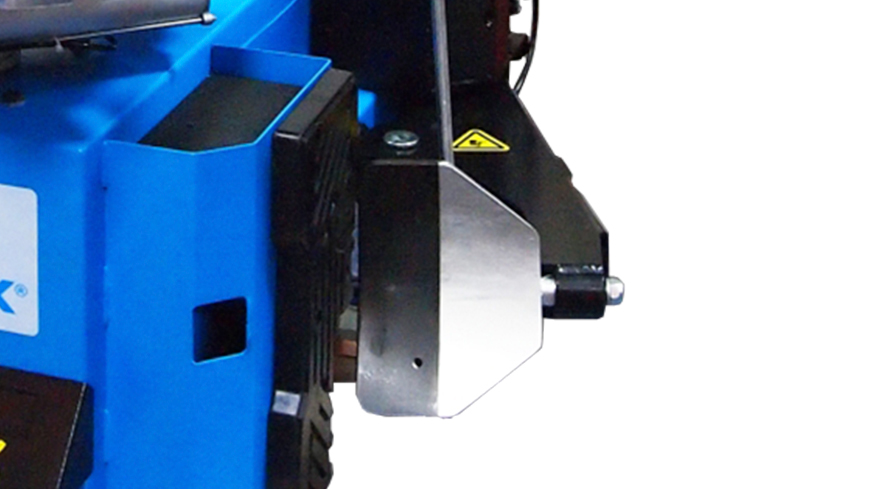

Sculpted hammer

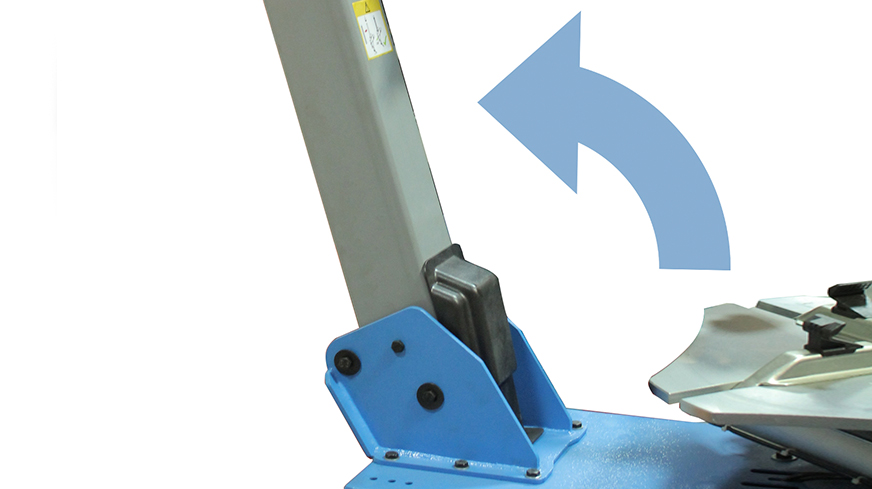

Pivoted pneumatic arm

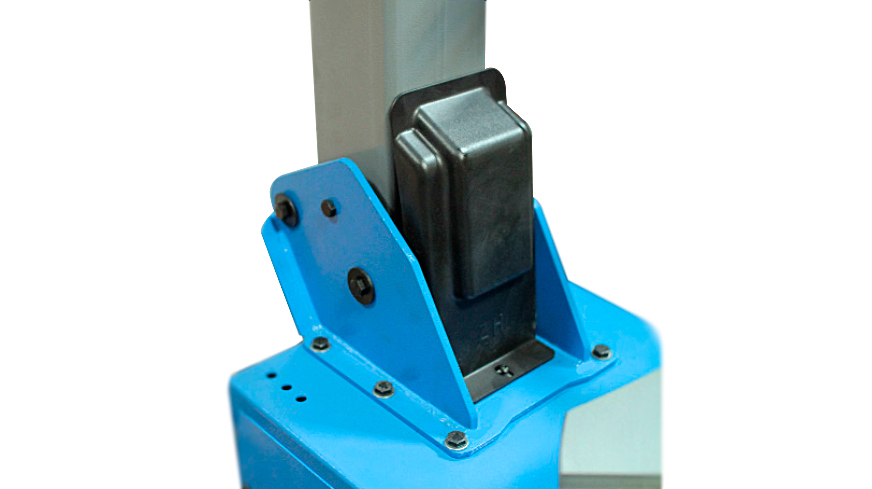

Reinforced construction

External fixing of 10-21 "rims

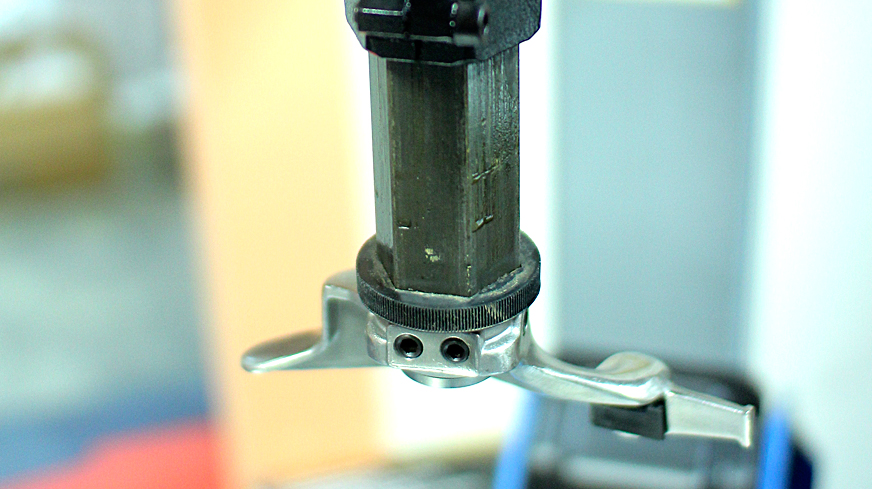

Hexagonal spindle

Panel with control pedals

Plastic accessories

Internal elements

Multidimensionality

Functionality

| Power of motor | 0,75 [kW] |

| Power supply | 400 [V] |

| Noise level | 70 [dB] |

| Outside clamping | 10” - 21” [cal] |

| Inside clamping | 12” - 24” [cal] |

| Max rim width | 14” [cal] |

| Max wheel diameter | 41” [cal] |

| Bead-breaker force | 2500 [kg] |

| Air pressure | 8-10 [bar] |

Product description

The CASC-505 tire changer is designed for mounting and dismounting tires from passenger cars, vans and motorcycles. In the case of the latter, it is enough to purchase additional equipment in the form of a suitable adapter in order to easily remove the motorcycle tire from the rim. Additional reinforcements and a hexagonal guide pin guarantee safe operation in conditions requiring higher strength. The presented model of the brazier is characterized by a pneumatically controlled and blockable tilting main arm, enabling quick and safe replacement of tires.

This is a very important aspect of the work of any vulcanizer, because the machine uses solutions that allow the replacement of tires with a minimized risk of rim damage. In addition, the design of the device, which works in the most extreme conditions in terms of strength and load, deserves attention.

The CASC-505 tire changer is designed for wheels up to 24 "in diameter (internal mounting rims), unlike CASC-502, which is characterized by a smaller range for rim mounting. In addition, this model has a table with four jaws, controlled by solid and reliable actuators. The machine is characterized by high quality of mechanisms controlling both electrical and pneumatic installations. The hammering ram used in CAS505 allows to obtain a force of 2,500 kg, and its contoured shape makes it easier to remove the tire in a significant way.

This product does not have an auxiliary arm - there is the possibility of additional equipment:

You can equip the machine with an auxiliary arm to support the tire pressure during disassembly and assembly of tires for both standard, low profile and runflat tires (see the auxiliary arm).

Advantages:

- Stable and massive construction

- Versatile use - suitable both for passenger car tires and motorbikes (can be used stationary in the workshop, but also as a mobile service equipment)

- A professional solution for professional workshops

- Internal fixing of rims up to 24 inches

- Easy and convenient control using foot pedals

- High quality pneumatic, electrical and mechanical components

- Large actuator of the punching arm

- A massive table - controlled by two cylinders

- Protection against damage to the rim

- Possibility of changing the power supply from 400V to 230V

Optional multifunctional right help arm for the low profile tyres and run flats (CAM113/505).

There is a possibility of additional equipment for the inflator.

Frequently Asked Questions

What is the difference between an automatic and semi-automatic batching machine?

The main difference is due to the design of both machines. In the case of semiautomatic assemblies, we have to deal with the arm swinging side by side. At the machine, the arm is pneumatically controlled and tilts backwards. The work area is larger, but also the comfort of work is increased.

Does the tire changer support runflat tires?

The CASC-505 tire changer is able to handle this type of tires. However, we recommend using an auxiliary arm.

|

Model |

Internal fixing |

External fixing |

|

502S |

10-17 [inch] |

12-21 [inch] |

|

502 |

10-18 [inch] |

12-22 [inch] |

|

505 |

10-21 [inch] |

12-24 [inch] |