+48 509 842 703

lub +48 514 305 545

albo napisz

biuro@kbglobal.pl

Masz pytania techniczne?

Zadzwoń

+48 505 035 611

albo +48 511 664 222

| Capacity | 4000 [kg] |

| Power of motor | 2,2 [kW] |

| Max. lifting height | 1900 [mm] |

| Rise / drop time | 45/25 [s] |

| Min. height of arm | 105 [mm] |

| Range of arm lengths | Front 700mm - 1400mm, Rear 900mm - 1400mm |

| Width between columns (internal) | 2649 [mm] |

| Width between columns (external) | 3412 [mm] |

| Noise level | ≤ 70 [dB] |

| Oil pressure | 200 [bar] |

| Power supply | 230/380 [V] |

| Width between carrages | 2395 [mm] |

| Power unit | electromagnetic |

| Powder coating (RAL) | 5002, 1018 |

| Quantity of hydraulic oil | 10 [l] |

| Quality of concrete | B25 |

| Thickness of concrete | 250 [mm] |

| Number of columns | 2 |

| Net / Gross weight | 670/690 [kg] |

| Working temperature | -5/+40 [°C] |

| Lock system | quadruple automatic electromagnetic |

| Type of hydraulic oil | 46 |

| Type of lift | two-post, with bottom stabilizer frame |

| Height of lift (posts) | 2883 [mm] |

Automatic two-column car lift on the CASTEX QJY4.0-D6D frame with a lifting capacity of 4000 kg is designed for work with passenger and delivery vehicles, whose total weight does not exceed 4 tons.

The stability of the lift and the lifted vehicle guarantees a reinforced structure of the load-bearing elements and a lower frame connecting the lift column, providing additional stiffening for the entire structure. The staggered side frames also have a significant impact on the stability of the system by increasing the contact area of the lift with the ground and optimizing the weight distribution of the vehicle lifted.

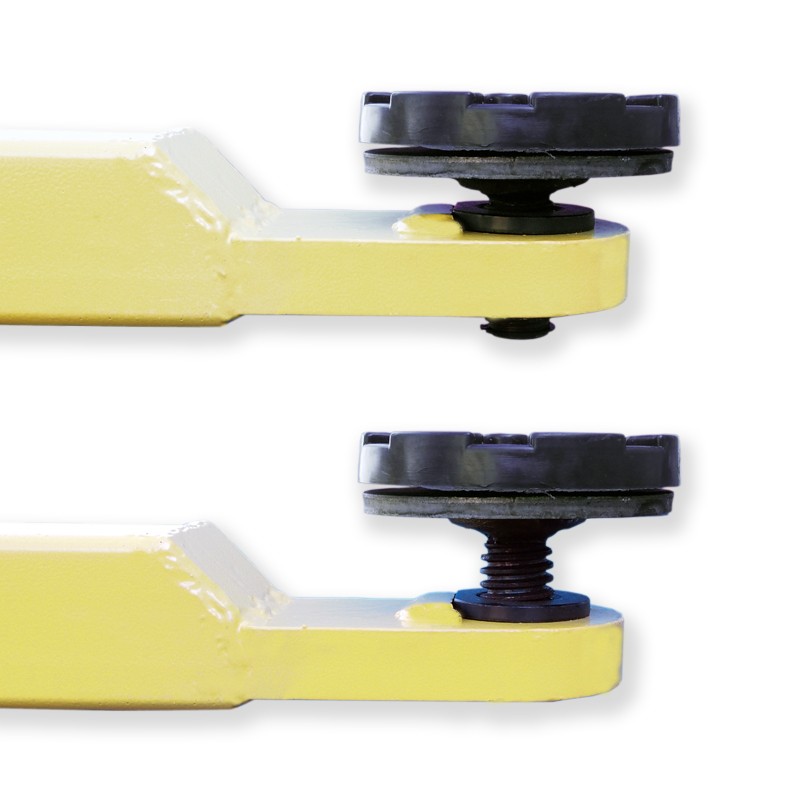

The lift is equipped with safety locks designed in SafetyOn technology, which was created with the user's safety in mind. Its main assumption is a system of locks still remaining in the safety position. They are unlocked only when the operator presses the button. When the button is released, the locks return to the safety position. This solution prevents erroneous deactivation of the security system and reduces the possibility of uncontrolled leaving the vehicle to zero.

The device uses a number of proven solutions to optimize the speed of your workshop. One of such solutions is the automated control of the electrohydraulic unit and the safety interlock system.

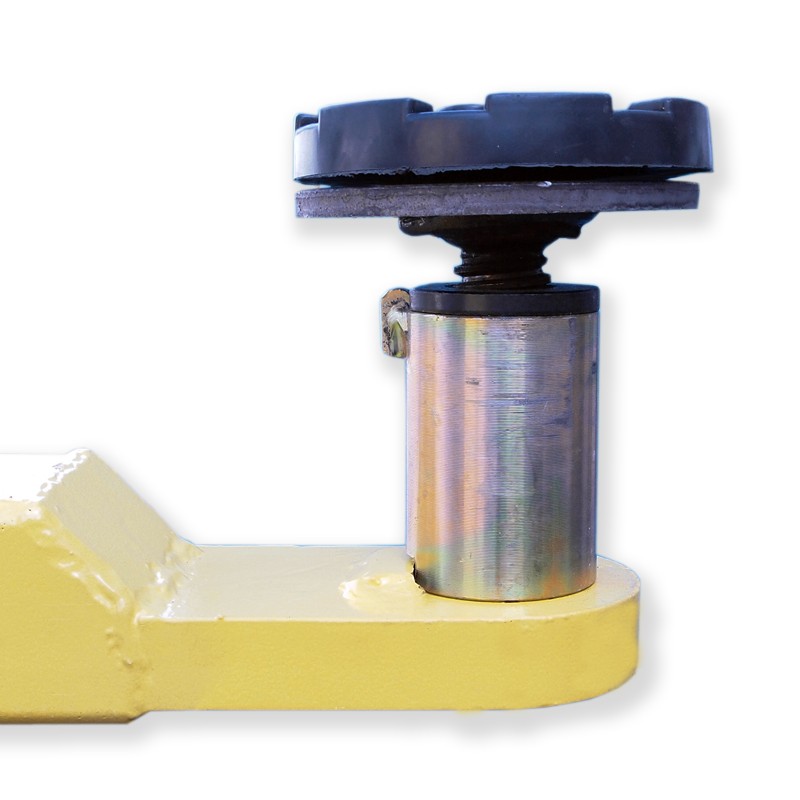

The range of adjustment of subliminal grips and a set of adapters makes it easier to work with cars with higher suspension.

The assembly has been simplified by pre-installation of most elements already at the production stage, and the lift includes a set of mounting anchors. At the order stage, it is possible to change the power supply of the lift with a voltage of 400V for 230V. Along with the lift, the customer receives the complete documentation necessary for proper use and maintenance, allowing for reporting the lift from the Office of Technical Inspection.

Features:

- lifting capacity 4000kg,

- reinforcing lower frame,

- reduced sublingual grip point with height adjustment,

- set of increasing adapters,

- automated service,

- stable reinforced structure,

- security locks in SafetyOn technology,

- simplified assembly,

- mounting anchors in the set,

- optional 230V power supply,

- CE certificate.

What is the difference between an automatic lift and a semi-automatic lift?

The basic difference is the design of the lift. Synchronizing ropes, electrical and hydraulic cables in the elevator connected to the bottom are routed at the level of the floor and secured with a passage guard. In a hoist with a structure where the columns are pinned together, all connecting elements are transferred to the top of the hoist, which allows leaving free passage between the columns.

What are the requirements for flooring and installation?

A concrete floor type C20 / 25 (formerly class B25) with a minimum thickness of 250 mm and dimensions 1000mm x 4000mm and an electrical connection 400V / 230V are required for the installation of the lift. Detailed information and technical drawing can be found in the DOWNLOAD tab.

Which hydraulic oil should be used?

Use 10 liters of HV / HL 46 hydraulic oil.

Automatic wheel balancer CASB-2000C for passenger cars, vans and motorcycle.

Automatic wheel balancer CASB-96AN for passenger cars, vans and motorcycle.

Automatic balancing machine CASB-99A for passenger cars, vans and motorcycles.

Semi-automatic wheel balancer CASB96B for passenger cars, vans and motorcycle.

Semi-automatic tyre changer CASC502S for wheels of passenger cars

and vans.

Automatic tyre changer CASC505 for passenger, vans and motorcycles tyres.

Semi-automatic tyre changer CASC502N for wheels of passenger cars

and vans.

A four-column car lift adapted to handle geometries with a lifting capacity of 5000kg.

Semi-automatic two-column lift with adjustable column spacing and lifting capacity of 3000 kg.

Semi-automatic two-column car lift with 3000kg lifting capacity.

Automatic two-column lifter combined with a top with a lifting capacity of 4000kg.

Automatic two-column lifter on a frame with a lifting capacity of 4000 kg.

Single step double piston compressor oil tank with a capacity of 200 liters of capacity 320 l/min.

Two-stage with twin piston oil compressor 270 liters with a productivity of 476 l/min.

Two-stage with twin piston compressor capacity of 270 liters with pump type 4900B with a productivity of 514 l / min.

QJY3.2-1 scissor lift with a lifting capacity of 3200 kg.

3.5 ton straight hydraulic lift.

Motorcycle lift 360 kg.

Straight pneumatic / hydraulic duct lift 3,5 t.

Winch for 2T engines - Crane.

Automatic two-column car lift with a lifting capacity of 4000kg.

A four-column car lift adapted to handle geometries with a lifting capacity of 5000kg.

Automatic two-column lifter on a frame with a lifting capacity of 4000 kg.

Semi-automatic two-column car lift with 3000kg lifting capacity.

KB Global sp z o.o.

ul. Grunwaldzka 257

85-438 Bydgoszcz

NIP: 554 289 63 37

Obsługa klienta i dostawy:

ul. Ludwikowo 2C,

85-502 Bydgoszcz, Poland

Poniedziałek - Piątek

w godz. 9:00 - 17:00

Zapraszamy!

Masz pytania techniczne?

Zadzwoń

+48 505 035 611

albo +48 511 664 222